Dependendo do tipo de produto que é bombeado, a operação pode ser completamente comprometida caso a bomba errada seja utilizada. Isso porque diversos produtos químicos são altamente corrosivos, podendo causar vazamentos e acidentes graves, colocando a vida de todos os trabalhadores em risco. Por essa razão, é importante estudar os tipos de bombas pneumáticas de diafragmas disponíveis no mercado e suas respectivas tabelas de compatibilidade química.

Pneumatic diaphragm pumps are highly versatile and reliable, and when applied correctly, can provide a great cost benefit to the company. For them to deliver all their productivity and quality, it is necessary to choose the correct model for your application.

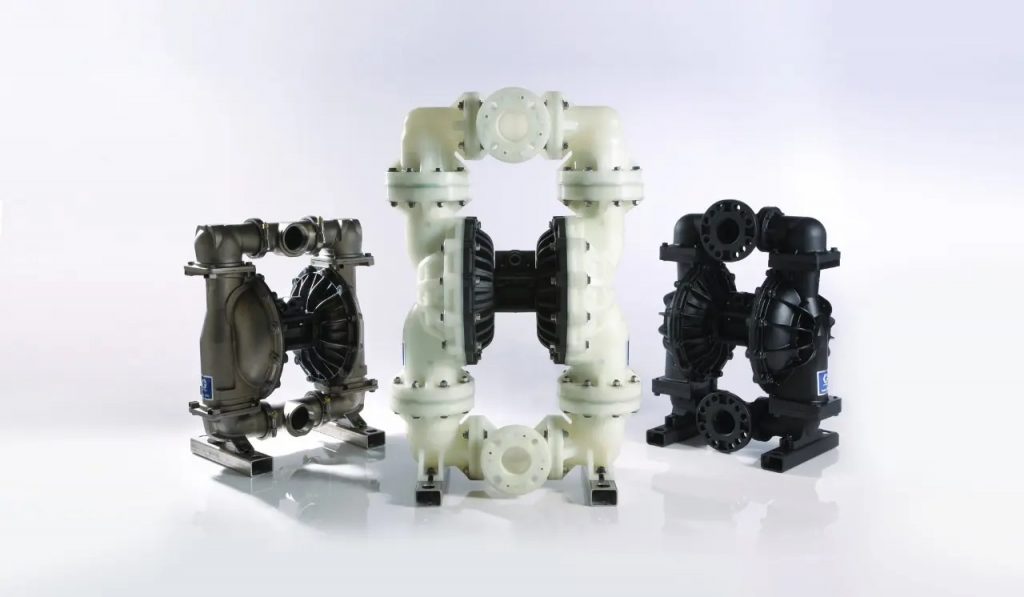

Before purchasing your pump, it is important to be aware of the differences between plastic and metal models and chemical compatibility for each application. By using the correct model, you can avoid accidents, increase productivity and ensure greater longevity for your pneumatic diaphragm pump.

metal pumps

Manufactured in aluminum, stainless steel, cast iron, or other metals, this type of pump is an excellent choice for applications where solids are handled, hazardous environments and in operations where high pressure is a concern (high pressure pump required). This type of pump can be grounded for added safety and can handle abrasion well.

In addition, they are robust pumps, very valuable in portable applications, as they allow for quick displacement and disassembly. This type of pump also has a high durability and guarantees several benefits for the company, such as:

· Abrasion-resistant parts;

· Less damage in mobile applications;

· Best cost-benefit;

· Can be grounded for greater safety in explosive environments;

· Easy cleaning and maintenance;

· Withstands a wide range of temperatures.

plastic pumps

Robust construction and leak resistant, pneumatic plastic diaphragm pumps are a very efficient alternative for operations involving chemical products. They are highly resistant to corrosion and, compared to metal pumps, are considerably lighter and can be transported easily.

Plastic diaphragm pneumatic pumps are made of polypropylene and PVDF, and can be applied in pumping chemical and petrochemical products; transfer of acids and caustics; water treatment; automotive services, among others.

This type of pump can be used outdoors, but performs better indoors. This is because it has a lower resistance to very high or very low temperatures. In this way, it cannot be exposed to UV light for a long time, so as not to damage its composition.

Pneumatic diaphragm pumps made of plastic ensure several advantages for the company:

They feature bolt-on, leak-free construction;

They are light bombs and can be transported easily;

have high chemical resistance;

They can be found in different sizes and materials;

They are portable and submersible;

It is possible to find versions for grounding, in order to meet the needs of the company.