The flow rate corresponds to the volume of fluid that can be transported within a given period. To get the maximum efficiency from your pneumatic diaphragm pump, it is necessary to know the flow rate of the equipment, which will help you to:

· Know if the pump is being efficient;

· Determining which pump is correct for your needs;

· Calculate efficiency based on cost savings.

For a higher flow rate, a larger pump is required. The higher the pump flow, the faster your operation and your productivity. In this way, the company will be able to meet an even greater demand and with more agility. An efficient pump ensures greater profitability and contributes to business growth.

Flow rate calculation

Regarding the pneumatic diaphragm pump, there are two types of flow that need to be measured:

· Total fluid that has passed through a sensor;

· Time-based data, such as gallons or liters per minute.

Thus, after determining the type of flow that will be measured, there are several tools and accessories that can contribute to this measurement, such as the electromagnetic, ultrasonic, turbine or magnetic meter. If your system does not have an accessory, there are other ways to determine this.

The first step is to find out how many strokes the pump makes per minute, and this can be done with the help of apps that track the count or even manually. With this information, you should refer to the pump information sheet as follows:

Above the flow curve, you can see the displacement per stroke, which is 0.49 gal. (1.85 L).

Stroke refers to the displacement of the diaphragm assembly when evacuating fluid out of the chamber. One cycle corresponds to two strokes, one on each side of the chamber, so to obtain the pump gpm it is necessary to multiply the number of strokes by the displacement per stroke.

To control flow rates from zero to maximum flow, simply increase or decrease the air flow or pump pressure. On pneumatic diaphragm pumps, the 1:1 ratio pattern can produce pressures up to 125 psi (8.6 bar). With flow rates up to 280 gpm (1,060 lpm), this equipment can deliver a wide variety of flows without the need for sophisticated and expensive controls.

Specialty pumps such as 2:1 high pressure units are capable of producing pressures up to 240 psi (16.5 bar). These high pressure units are generally used in applications that require greater force.

The importance of sizing the pneumatic diaphragm pump

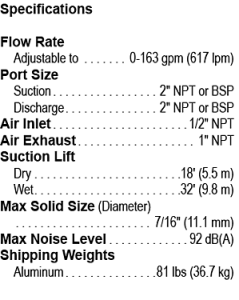

To ensure more efficiency and extend the life of your pump, you can increase the port size if possible. The correct sizing at the time of choose your pump is one of the most important factors.

For example, if you want to move 40 gpm (151 lpm) 10 feet (3 meters) high with a 1 inch pump, most manufacturers on the market can only achieve this flow rate by pumping water. Unfortunately, it would be necessary to make the pump work too close to its maximum capacity and stroke rate, leading to increased wear and decreasing pump efficiency.

To the size a bomb longer, you can run the pump at a reduced speed (with reduced strokes per minute), which will prolong the life of the pump and increase its efficiency.