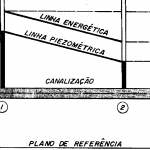

Adding head and flow for pumps arranged in parallel vs. serial.

Pumps can be arranged and connected in series or in parallel to provide additional head or flow capacity.

Series pumps – added head

When two (or more) pumps are arranged in series, the resulting pump performance curve is obtained by addition of your heads at the same flow rate indicated in the figure below.

Centrifugal pumps in series are used to overcome system pressure drop greater than a pump can handle alone.

- for two identical pumps in series, the head will be twice the head of a single pump with the same flow – as indicated in point 2.

With constant flow, the combined head moves from 1 to 2 – BUT , in practice, the combined head and flow rate move along the system curve to point 3.

- point 3 is where the system operates with both bombs working

- point 1 is where the system operates with a bomb working

Note that for two pumps with equal performance curves running in series

- the head for each pump is equal to half the handle at point 3

- the flow for each pump is equal to the flow at point 3

Operation of single-stage pumps in series is rarely found – more often multi-stage centrifugal pumps are used.

Parallel Pumps - Added Flow Rate

When two or more pumps are arranged in parallel, their resulting performance curve is obtained by sum of pump flows at the same head, as indicated in the figure below.

Parallel centrifugal pumps are used to overcome larger volume flows than a single pump can handle.

- for two identical pumps in parallel and the head held constant – the flow rate doubles compared to a single pump as indicated in point 2

Observation! In practice, the combined head and volume flow move along the system curve as indicated from 1 to 3.

- point 3 is where the system operates with both bombs working

- point 1 is where the system operates with a bomb working

In practice, if one of the pumps in parallel or in series stops, the operating point moves along the system resistance curve from point 3 to point 1 – head and flow decrease.

Note that for two pumps with equal performance curves running in parallel

- the head of each pump is equal to the head at point 3

- the flow for each pump is equal to half the flow at point 3

Note – for parallel operation

- zero flow or “shut-off valve” heads must match pumps

- unstable pump curves must be avoided

- Steeper pump curves are preferred

Source: https://www.engineeringtoolbox.com/pumps-parallel-serial-d_636.html