Within the industry, the pneumatic diaphragm pump is one of the most flexible and efficient equipment for transporting fluids, regardless of the industry. To guarantee the expected results, it is essential to have the correct pump, both in terms of its dimensioning and its chemical compatibility with the material being conveyed.

There are currently several types of positive displacement pumps, and using the correct pump can make all the difference, especially for those looking for more reliable operation with less downtime.

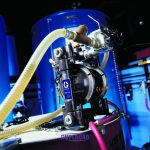

The pneumatic diaphragm pump uses compressed air to operate without the need for electrical power or sophisticated controls. This pump can be used in industry to displace different types of products, ensuring efficiency and safety, representing an excellent cost-benefit ratio.

In addition to high efficiency, pneumatic diaphragm pumps can deliver safe, shear-free transfer. In other words: when conducting delicate fluids, the pump can carry out transport without damaging the product.

Where can pneumatic diaphragm pumps be applied?

Due to their high versatility, pneumatic pumps can be applied in different sectors of industry, such as:

• Automotive;

• Ceramics;

• Chemistry;

• Construction;

• food and drinks;

• Navy;

• Mining;

• Oil and gas;

• Paints and Coatings;

• Pharmaceuticals;

• Water and Wastewater;

• And much more.

This equipment is capable of handling fluids safely and quickly. In addition, pneumatic diaphragm pumps also guarantee numerous advantages for companies.

• Can run dry without risk of damaging the pump or the system as a whole;

• Can pump fluids laden with solid particles without damage;

• Are self-priming pumps and can work in suction lift applications;

• Deadhead safely;

• Are shear sensitive, which means they do not cut or separate the product being transported;

• Does not require electricity to operate, and can be fully grounded;

• Features a low initial purchase price compared to other positive displacement pumps, making it an excellent alternative for industries of all sizes;

• They can be grounded and submersible, providing more safety (mainly in operations with hazardous fluids).