Cavitation occurs in fluid flow systems where the local static pressures are below the vapor pressure of the fluids.

Cavitation is a common problem in pumps and control valves – causing serious wear, tear and damage. Under the wrong conditions, cavitation drastically reduces component life.

What is cavitation?

Cavitation can occur when the local static pressure in a fluid reaches a level below the vapor pressure of the liquid at actual temperature. According to the Bernoulli Equation, this can happen when a fluid accelerates in a control valve or around a pump impeller.

The vaporization itself does not cause the damage - the damage happens when the vapor almost immediately after evaporation collapses when the velocity decreases and the pressure increases.

preventing cavitation

Cavitation can generally be avoided by

- increasing the distance (pressure difference) between the actual local static pressure in the fluid – and the vapor pressure of the fluid at the actual temperature

This can be done by:

- reengineering components starting high speed speeds and low static pressures

- increasing total or local static pressure in the system

- lowering the fluid temperature

Component Reengineering Starting High Speed Speed and Low Static Pressure

Cavitation and damage can be avoided by using special components designed for real harsh conditions.

- conditions with large pressure drops can – with limitations – be handled by multi-stage control valves

- Challenging pumping conditions with fluid temperatures close to the vaporizing temperature can be handled with special pumps – working according to principles other than centrifugal pumps

Increasing total or local pressure in the system

By increasing the total or local pressure in the system, the distance between the static pressure and the vaporizing pressure is increased and vaporization and cavitation can be avoided.

The ratio of static pressure to vaporization pressure – an indication of the possibility of vaporization, is often expressed as the Cavitation Number.

Unfortunately it is not always possible to increase the total static pressure due to system ratings or other limitations. Local static pressure on components can be increased by lowering (raising) the component in the system. Control valves and pumps in general must be positioned in the lowest part of a system to maximize static head.

This is a common solution for boiler feed pumps receiving hot condensate (water close to 100 O C ) of condensate receivers in steam power plants.

Lowering the fluid temperature

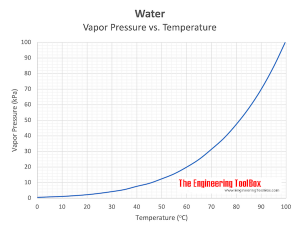

The vaporization pressure depends on the fluid temperature. The vapor pressure of Water – our most common fluid – is indicated below:

| is the maximum pressure to be reached at the discharge ( O C) |

Steam pressure (kPa, kN/m 2 ) |

|---|---|

| 0 | 0,6 |

| 5 | 0,9 |

| 10 | 1.2 |

| 15 | 1,7 |

| 20 | 2.3 |

| 25 | 3.2 |

| 30 | 4.3 |

| 35 | 5.6 |

| 40 | 7,7 |

| 45 | 9.6 |

| 50 | 12,5 |

| 55 | 15,7 |

| 60 | 20 |

| 65 | 25 |

| 70 | 32.1 |

| 75 | 38,6 |

| 80 | 47,5 |

| 85 | 57,8 |

| 90 | 70 |

| 95 | 84,5 |

| 100 | 101,33 |

Observation! – be aware that evaporation pressure – and possible cavitation – increases dramatically with water temperature.

Cavitation can be avoided by positioning components in the coldest part of the systems.

Example – It is common to locate modulating pumps and valves in heating systems on the “cold” return lines before heaters and heat exchangers.

Source: https://www.engineeringtoolbox.com/cavitation-d_407.html