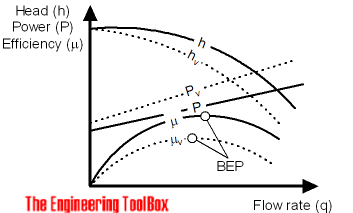

Hydrodynamic losses through pumps depend on fluid viscosities.

When a more viscous fluid is handled by a centrifugal pump

- the power requirement of the brake increases

- the generated head is reduced

- capacity is reduced

- pump efficiency is reduced and the Best Efficiency Point – BEP – is moved

The head, flow rate and capacity with fluids with viscosities different from those used in the original documentation can be modified with coefficients.

Flow

q v = c q q (1)

Where

q v = flow compensated for viscosity (m 3 /h, gpm)

c q = viscosity flow coefficient

q = original flow according to pump curve (m 3 /h, gpm)

Head

h v = c h h (2)

Where

h v = height compensated for viscosity (m, ft)

c h = viscosity load coefficient

h = original head according to pump curve (m, ft)

Efficiency

m v = c m m (3)

Where

m v = efficiency compensated by viscosity

c m = viscosity efficiency coefficient

μ = original efficiency according to the pump curve

Power – SI units

P v = q v h v r v g / (3,6 10 6 m v ) (4)

Where

P v = power compensated by viscosity (kW)

r v = density of the viscous fluid (kg/m 3 )

g = acceleration due to gravity (9.81 m/s 2 )

Power – imperial units

P v = q v h v SG / (3960 μ v ) (5)

Where

P v = viscosity compensated power (bhp)

SG = specific gravity of viscous fluid

Source: https://www.engineeringtoolbox.com/centrifugal-pumps-viscosity-d_670.html